Receiver KWE-a or LWE-aA view inside the receiver. Very well visible are the tubes

RV2P800 in there sockets. Right is shown the 2

gasfilled bulbs for protecting the HF-input. Very high voltages due to

lightning in heavy thunderstorms are fed back then through them to earth. The

various coil sets for the several frequency bands above right are turned

around via a kind of "Maltheser Kreuz" principle. When it begins turning, the

contacts are lifted (open contacts), then the coil set turnes to its position,

stops turning and after that the contacts are closing again. In this way the

contacts are kept pure and clean.

This is a master piece which has put a technical standard that, in my

opinion, was the world's best battery tube powered communication

receiver for that freq. range; if you imagine that is was designed (I

suppose) 1936-1938. Not only the mechanical construction, but the

circuit design as well were outstanding (advanced). Look for example the

design of the IF stages with the band width selection control and/or the

separate AVC (AGR) amplifier among many other things. This technical

effort is in my opinion quite under valued, from the technical point of

view it isn't important that an item (artefact) is too expensive to be

produced compared to similar Allied artefacts.

Regenerative receivers were an exception (I mean super-regenerative,

not straight forward receivers, because the TornE-b and/or Lo 6 K 39

were very good, although no super heterodyne), these were used only for

small portable sets But the British used this same principle for the

B-set of the WS 19 as well.

The major difference between receiver standards from Europe and the

US were for the latter that they were using tubes extensively (quantity)

which, caused by economical factors, wasn't possible in Europe. US

communication receivers often used twice the number of tubes as these

were utilised in Germany, Holland and Britain. An other important factor

which is often neglected is the fact that the Germans were very well

orientated on what was going on in the US and many US articles and

publications were discussed by them. Probably because so many German

scientist were immigrated to the US and some still had links to Germany

kept alive.

E52b Køln

Attenuation De-Tuning

Bandwidth Wide

Bandwidth Narrow

Attenuation De-Tuning

Bandwidth Wide

Bandwidth Narrow

3 db

5 kHz

0.2 kHz

40 db

10 kHz

1 kHz

60 db

13 Khz

2 kHz

You get a first impression from it by looking at the two hinging lids

that are lifted to show some of the gadgets under them when they are

normally closed. You probably notice the clean layout of the front panel

and the functional shape of the controls. And that was done in the days

that "ergonomics' was an unknown word.

The dimensions of the radio are 24.1 cm high, 44.6 cm wide and 36.9 cm

deep. Its mass is a massive 42.8 kg (94 lbs.). The set can be run from

110-230 V. a.c., from which 60-96 watts are consumed, or from a 12 V.

battery. A vibrator power supply is built in.

There are five frequency ranges, as follows:

(Range I ) 1.5-3 MHz, white scale on the dial.

( Range II ) 3-6 MHz, red scale.

( Range III ) 6-10 MHz, yellow scale.

( Range IV ) 10-17.6 MHz, blue scale.

( Range V ) 17.6-25 MHz, green scale.

The ranges are selected by the oblong control to the left of the

indication 'FrequenzeI.nstellung" (frequency adjustment). The frequency

the radio is tuned to can be read from the semicircular dial. To avoid

reading the wrong scale the frequency ranges are tabulated to the left

of the dial and the table also shows the colour of the scale to be read.

Tonschreiber d (Dora)

AEG Magnetophone

Frequency: 50-6000hz. Bandspeed 77cm/s.Roller capacity 10min.Factory

AEG. in berlin.Produced 1941 but product started 1940/41. Color

military green until 1943.1943 to 1945 antracit.5 batteries 2,4v NC-28

in serie and vibrator power.

Frequency: 50-6000hz. Bandspeed 77cm/s.Roller capacity 10min.Factory

AEG. in berlin.Produced 1941 but product started 1940/41. Color

military green until 1943.1943 to 1945 antracit.5 batteries 2,4v NC-28

in serie and vibrator power.

Tonschreiber c (Cesar)

Frequency: 200-2000hz. Bandspeed 19cm/s.Roller capacity 11min.factory

AEG

in Berlin.Produced 1941.Color military green until 1943,thereafter

antracit. Powering the unit with steel-spring mecanism and 4.5 v dry

battery for microfon and band .Steel-spring driving the

band-motor.Weight ca 12kg. The band was made of 6.5mm

Azetylcellulosefilm

Frequency: 200-2000hz. Bandspeed 19cm/s.Roller capacity 11min.factory

AEG

in Berlin.Produced 1941.Color military green until 1943,thereafter

antracit. Powering the unit with steel-spring mecanism and 4.5 v dry

battery for microfon and band .Steel-spring driving the

band-motor.Weight ca 12kg. The band was made of 6.5mm

Azetylcellulosefilm

Tonschreiber Ton S.b1

Freqency 60 -5000hz.bandspeed 9-120cm/s.Producer AEG.Berlin 1939.Color

antracit.Power 110 to 250v ac.Tubes: 7 RV12P2000, 2 LS50,1 Glimmtube

UR110. Weight 61kg.

Freqency 60 -5000hz.bandspeed 9-120cm/s.Producer AEG.Berlin 1939.Color

antracit.Power 110 to 250v ac.Tubes: 7 RV12P2000, 2 LS50,1 Glimmtube

UR110. Weight 61kg.

Pic from

S.E.Blacklock

Pic from

S.E.Blacklock

The

Germans led the efforts to improve magnetic recording.

AEG developed the Magnetophone, and improvements in the chemical

engineering of polymers allowed its partner BASF to ship the first

magnetic tape in 1935 — a foil of cellulose acetate coated with a

lacquer of iron oxide bound with additional cellulose acetate. Most

developed nations continued to work on magnetic tape for commercial and,

with the approach of World War II, military applications.During the War,

the Allies became aware of the German superiority in this technology. As

U.S. forces advanced late in the war, a young technician from the Army

Signal Corps, John T. “Jack” Mullin, was assigned to capture and analyze

enemy radio equipment. He stumbled upon an advanced Magnetophone, and

U.S. work soon progressed in this area.According to one popular story,

in 1945, General Dwight D. Eisenhower wanted to record a message to the

German people, which he did using captured German tape. However, the

tape had not been completely erased, and Hitler’s voice, so the story

goes, could be heard intermittently along with that of Eisenhower.

Eisenhower ordered that no more captured tape could be used, and ordered

Major John Herbert Orr to use captured German scientists to set up an

American tape manufacturing facility.Afterwards, Orr returned to

civilian life in the United States where he went into partnership with

Alexander Poniatoff. Their company — Ampex — began producing magnetic

tape and magnetic recorders (German patent rights on the recorders had

been seized by the U.S. Alien Property Custodian).Meanwhile, Mullin had

also returned from the War, and in 1946 demonstrated the advanced

Magnetophone to a meeting of the IRE, predecessor to the IEEE. There,

according to Mullin's own account, it created quite a sensation.

Word got back to Bing Crosby, who was a pioneer in the area of

entertainer-as-entrepreneur (think Oprah Winfrey today). With Mullin as

a consultant, Crosby began to use the Magnetophone to record his radio

programs. Soon Mullin entered an arrangement with Ampex to supply the

equipment and recording medium, and the company and the technology took

off.The full Bing Crosby story will make for a good “Engineering & Pop

Culture” piece in this space some day. The important fact is that

magnetic tape became a crucial recording medium for the birth of the

information age, used for video as well as audio, in formats such as

cassette and 8-track, for sound recording in motion pictures (replacing

optical sound tracks), and eventually for digital recording, including

computer memory.There were many other players around the world: 3M in

the United States; a reformed BASF in Germany, Philips in the

Netherlands; and Sony in Japan. Ampex always remained a leader, and in

1995, Ampex successfully spun off its media division as Quantegy. Over

the past few decades, digital recording has all but completely

supplanted analog recording. Various new media, including those that

employ lasers, are now more widely used to record digital signals.

Although magnetic tape will continue to be used for niche applications,

it is no longer as ubiquitous as it once was. We tip our hat to

Quantegy and the closing of another chapter in electrical history.

Nahfeldhpeiler P.57n

Frequence 3.0 to 20 Mhz, mod A1-A3.Producer

Telefunken.berlin.In war ca

1941.Constructed 1935.Color,marine blue.Constructed for moving

army.police and airports.This unit was mounted in special cars.Battery 4

x 4.8v NC10 and anode battery 150v Pertrix type 307.Tubes: 1 RE084, 3

RE084K and 2 RES094.IF-968khz.

Frequence 3.0 to 20 Mhz, mod A1-A3.Producer

Telefunken.berlin.In war ca

1941.Constructed 1935.Color,marine blue.Constructed for moving

army.police and airports.This unit was mounted in special cars.Battery 4

x 4.8v NC10 and anode battery 150v Pertrix type 307.Tubes: 1 RE084, 3

RE084K and 2 RES094.IF-968khz.

This site was last updated

01/04/10 Home

.

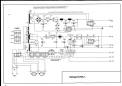

Here is the cheme to power unit for

Kwea/Lwea.Soon the picture of the unit.

Here is the cheme to power unit for

Kwea/Lwea.Soon the picture of the unit.